|

AVAproject users have come to depend on detailed component material lists automatically generated from AVAcad elevations. Frame construction preferences provide a variety of additional options to control the way in which frames are deconstructed - down to the last detail.

AVAcad is able to deconstruct frame elevations based on construction preferences set forth by the selected manufacturer. In addition to pricing, AVAware product catalogs contain parameters that govern exactly how the frame is to be assembled. This include joint and welding options, field splices and choices such as when to use filler pieces as opposed to mullion cut-outs.

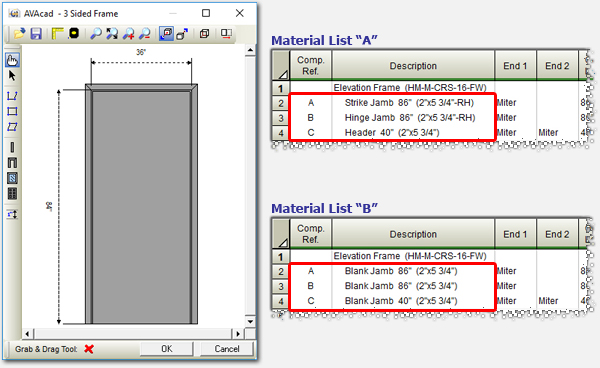

For example, the sidelite frame depicted below contains a partial mullion that can be constructed by using either a black jamb with a filler strip as shown in 'Material List A' or mullion with a cut-out as shown in 'Material List B'.

The partial mullion is only one example of the variations that can occur in the material lists generated for different manufacturers. This becomes even more apparent when having to price the frame based on their catalog pricing. Some manufacturers chose to price joints as a single unit, while others price cuts and welds as separate items. In any case, AVAproject is aware of these details and build the material lists according.

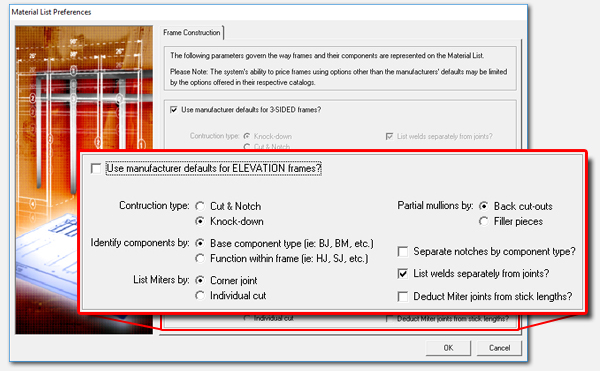

While the decision of how these types of components are constructed is typically made by the manufacturer, there are circumstances in which distributers may wish to assert their preferences on how a frame is configured. It's for this reason that AVAproject allows users to override manufacturers' preferences in favor of their own.

The 'Material List Preferences' dialog (accessible through the 'Project' menu) allows users to make selections that will govern the way in which frame elevations are constructed and appear in the material list.

The following is another frame example, with two variations of the material list based on user defined preferences. In 'Material List A', components are described based on their function (ie: hinge jamb, strike jamb, etc.), while in 'Material List B' those same components are simply identified as "black jambs". This allows manufacturers and distributors to use coordinating nomenclature to identify components for ordering and inventory purposes.

It's important to note however, that the hardware preparations required for each component are clearly listed in either case.

Three-Sided Frames

The ability to control the construction details of frames is not limited to AVAcad elevations. Many of the same options offered for elevation frames are also available for the standard three-sided variety.

This becomes especially useful when managing pre-configured "stock" frames, that often come with hardware preparations already done. A distributor may choose whether to draw stock frames from inventory using 'hinge jamb/strike jamb' nomenclature, or to fabricate custom configurations using 'blank jambs'.

Once again, AVAproject can easily accommodate either situation by allowing users to determine the nomenclature used to identify individual frame components. One can even go so far are determine whether frames will be delivered 'knock-down' with tabs or cut and welded. Even welds can be listed separately to facilitate labor cost estimates.

AVAproject was designed to accommodate all the construction nuances that architectural opening distributors might encounter in the projects. The Material List options are one more example of the flexibility offered, and can be used in combination with the myriad of additional construction options available in the system.

|